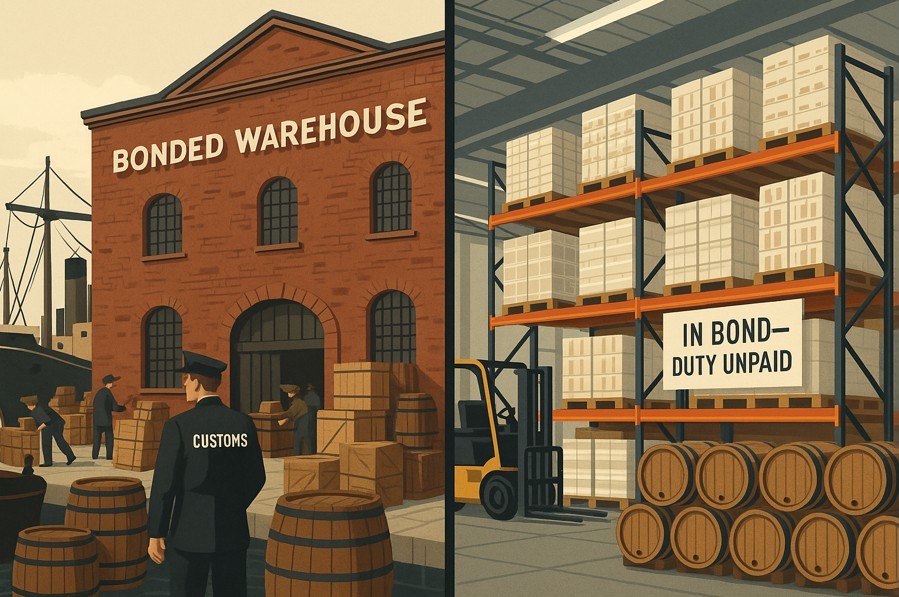

When you think about moving wine, beer, or spirits, you might picture ships unloading at busy ports or HGVs making their way along motorways. But beverage logistics involves far more than transport alone. One area which is often overlooked but absolutely vital is bonded warehousing.

With a history stretching back almost three centuries, bonded warehousing allows wines, beers and spirits to be stored securely, compliantly and tax-efficiently. Today, it remains a cornerstone of how beverages move through the UK market, supporting importers, producers and retailers alike.

Did You Know? Bonded Warehousing Started in the UK

The system of bonded warehousing has its roots in Britain. Back in 1733, Sir Robert Walpole, often regarded as the country’s first Prime Minister, proposed that imports such as tobacco and wine should be held in secure warehouses, with duties only paid when the goods were released for sale. His “excise scheme” was rejected at the time, but it set the foundations for what was to come.

Forward to 1803, when the UK officially adopted warehousing under bond. At first, this was limited to dockside warehouses, where goods were held under customs supervision with duty deferred until release. For importers of wine and spirits, the change was revolutionary: they no longer had to raise large sums of cash upfront, and stock could be matured, stored or sold when market conditions were right.

The Customs Consolidation Act of 1853 then expanded the system, allowing bonded warehouses to operate outside of docks and not just within port estates. From there, the model spread across Europe and then worldwide. By the late 19th century, bonded warehousing had been established in India under the Sea Customs Act of 1878, and in the United States, it evolved into the “bottled in bond” system still recognised today in the spirits sector.

Bonded Warehouses as Landmarks of Trade

These warehouses were once some of the most important buildings in Britain’s ports and canal towns, their barred windows and thick walls designed to guard goods until duty was paid.

- Liverpool: By the late 1800s, the city’s bonded tea warehouses were among the largest in the world, holding vast quantities of taxable imports under HM Customs supervision. They were symbols of Britain’s dominance in global trade.

- Stourbridge: Built in 1779 on the canal network, the Stourbridge Bonded Warehouse is a rare survivor of this era. Originally used to hold taxable goods such as spirits and tobacco, its iron-barred windows still hint at the value of what once lay inside. Today, fully restored, it serves as a community hub and heritage site managed by the Stourbridge Navigation Trust. Visitors often ask why it was built and what it once stored a reminder of how central bonded warehousing was to local and national commerce.

- London Docks: In their 19th-century prime, London’s bonded warehouses stored millions of gallons of rum, wine and brandy. Though many have since been redeveloped into residential and commercial spaces, their legacy is embedded in the city’s history of international trade.

Why Bonded Warehousing Mattered and Still Does

For beverage importers, bonded warehousing changed everything. Before the system, duties had to be paid upfront or sureties arranged this was a financial strain that forced many into quick sales at poor prices. Bonded storage solved this by:

- Deferring taxes until the stock was released.

- Making international trade accessible to smaller importers without vast capital reserves.

- Allowing wines and spirits to mature properly before reaching the market.

- Enabling re-labelling, re-packing or blending “in bond” to meet local market demands.

- Supporting re-export, with duty remitted where goods were shipped out again.

In short, bonded warehousing provided both flexibility and financial breathing space and all these advantages remain just as relevant today.

Dos and Don’ts of Using Bonded Warehousing

DO:

- Keep documentation accurate and aligned with HMRC requirements.

- Rotate stock carefully; wines and beers may have specific shelf-life needs.

- Use bonded storage as a strategic tool for managing cash flow.

- Choose warehouses with proven expertise in handling beverages.

- Take advantage of re-labelling or re-packing in bond when entering new markets.

DON’T:

- Release goods without verifying their duty status.

- Assume every bonded warehouse is the same; some specialise in cased wine, others in bulk spirits.

- Forget that customs supervision doesn’t cover insurance against loss or damage.

- Mix consignments without ensuring every SKU is properly documented.

- Overlook the time needed for clearance when releasing stock from bond.

The Role in UK Beverage Logistics Today

Fast forward to today, and bonded warehousing continues to be an integral asset to the drinks trade through:

- Deferred Taxation: Duty and VAT are suspended until release, easing cash flow.

- Market Responsiveness: Goods can be re-packaged or re-labelled in bond to meet demand.

- Risk Mitigation: Stock held close to ports or consumer hubs helps buffer supply chain disruptions.

- E-commerce Integration: Online drinks retailers increasingly use bonded facilities to fulfil direct-to-consumer orders while retaining tax advantages.

Frequently Asked Questions (FAQs)

What is a bonded warehouse?

A secure storage facility where goods are held under customs control without immediate duty payment.

Why are bonded warehouses important for drinks?

They provide cash flow advantages, ensure compliance, and allow wines and spirits to be stored until market-ready.

Can small producers use bonded warehouses?

Yes. Facilities range from major port warehouses to smaller, more specialised stores.

Are bonded warehouses still under lock and key from customs officers?

Not anymore. Since 2016, most UK bonded warehouses are supervised by licensees under HMRC compliance. Direct customs control remains only for certain commodities, such as duty-free stock and precious metals.

At Kukla UK, We Help You Make Bonded Storage Work

Whether you’re moving a few pallets of bulk wine or full container loads, bonded warehousing remains a highly effective way to manage costs and keep supply chains agile. Kukla UK works hand-in-hand with trusted bonded facilities to ensure your goods are stored securely in the right bonded facility, released compliantly and delivered where they need to be on time and intact.

Photo credit: AI-generated image for illustration only.