When you think about logistics for wine, beer, or spirits, the first things that may come to mind are vineyards, cellars, or shipping routes. But there’s a far less glamorous hero behind the scenes, this is the humble pallet.

At Kukla UK, we understand that successful beverage logistics isn’t just about bottles and containers; it starts at the base, with how those bottles are packed, stacked and shipped. Get this wrong, and the consequences can be catastrophic. Here’s why pallets matter, and how to ensure they’re working for you, not against you.

Why Pallets Are Crucial in Beverage Logistics

A pallet is a flat platform, usually wooden, on which goods, including cases of wine or spirits, are stacked for transportation. They make it easier to load, move and store goods efficiently and safely. But not all pallets are created equal and not all suppliers pay attention to how goods are loaded onto them.

A well-packed pallet reduces the risk of movement, damage and even collapse during transit. Poor palletisation can lead to delays, refusals at collection, or worse, a shattered load upon delivery.

The Pallet Types That Keep Your Bottles Moving

There are two main types of pallets used in beverage logistics:

- Euro Pallets (800 x 1200mm)

Widely used across Europe, these pallets are the standard for transporting wine and spirits. - VMF Block Pallets (1000 x 1200mm)

Specifically designed for transporting bottles and glass, these units offer a slightly larger footprint and are commonly used in the industry, especially for full container loads.

How Many Cases Fit on a Pallet?

A standard pallet can hold between 48 to 56 full 12-bottle cases of wine or spirits, stacked typically four layers high. Depending on the container size, you can fit:

- 11 Euro pallets in a 20ft container

- 24 Euro pallets in a 40ft container

- 10 VMF pallets in a 20ft container

- 21 VMF pallets in a 40ft container

It is one less pallet for reefer containers i.e. 10 Euro pallets in a 20ft container.

Loading Pallets: Best Practices That Save Bottles

Correct loading is essential. As one of our team noted, “You may be thinking about cellars and tastings, but if you don’t talk to your suppliers about how your goods are loaded, you could be inviting disaster.”

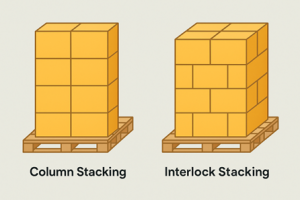

Interlock stacking increases stability

Interlock stacking is a method of arranging boxes on a pallet in a way that increases stability by overlapping the layers, rather than stacking boxes directly on top of each other in straight columns.

How it works:

In interlock stacking, each layer of boxes is rotated or offset so the boxes straddle the seams of the layer below, similar to how bricks are laid in a wall. This creates a more unified structure where the weight is more evenly distributed and each layer supports the one above.

Why it’s better:

- Greater stability during transit

- Reduces shifting or collapse when the pallet is moved

- Minimises damage to goods caused by sudden jolts or uneven surfaces

- Ideal for mixed loads or when using boxes of slightly varying sizes

However, it’s worth noting that column stacking can sometimes allow for more boxes per pallet and is preferred when box strength is high. However, for most beverage shipments, especially those containing fragile items like bottles, interlock stacking is the safer choice.

See the diagram above to compare Column vs. Interlock stacking

Dos and Don’ts of Pallet Loading

DO:

- Evenly distribute weight.

- Stack heavy items at the bottom.

- Use interlock stacking where possible for better stability.

- Band and shrink-wrap goods securely.

- Use cardboard between layers for stability and protection.

- Follow weight limits, maximum 1,200 kg, including the pallet.

DON’T:

- Stack in columns without support they collapse like dominoes.

- Allow goods to overhang the pallet edge.

- Forget to use anti-slip sheets or edge protectors for fragile items.

Avoid Mixing Items on the Same Pallet

- One critical but often overlooked point is consistency. If you’re mixing different products on the same pallet, for example, wine and spirits, or different SKUs, you must be absolutely sure all the documentation is complete and accurate for every item. If there is a customs issue with just one part of that mixed pallet, the entire load can be detained. For smooth clearance, we recommend keeping pallet contents homogeneous whenever possible, which simplifies paperwork and reduces the risk of border delays.

Automation vs. Manual Loading

Large beverage producers, for example, champagne houses, utilise automated palletisation and shrink-wrapping. But many other suppliers are still loading pallets manually. Both are fine, but with the manual process, attention to detail becomes vital. Our drivers cannot accept a misloaded pallet and will need to re-pack it, which costs time and money.

Labelling and Documentation Tips

One of the most common causes of delays in beverage logistics, particularly at customs checkpoints, is incorrect or insufficient pallet labelling.

To avoid unnecessary holdups or even detainment:

- Clearly label each pallet with:

- Shipment reference numbers

- Product codes or SKUs

- Quantity and description of goods

- Handling instructions (e.g. Fragile, Do Not Stack, This Way Up)

- Include country of origin and destination labels, especially for export shipments.

- Match labels with documentation, packing lists, invoices, and customs declarations to ensure they correspond precisely to the contents of the pallet.

- For mixed product pallets (which we generally recommend avoiding), you must list every item accurately to prevent the entire load from being held up due to an issue with a single SKU.

Accurate labelling ensures your shipment can be swiftly processed through hubs, ports, and customs, keeping your supply chain smooth and predictable.

Compliance and Global Shipping Standards

When shipping internationally, wooden pallets must comply with ISPM 15 regulations, which require them to be heat-treated or fumigated to prevent the spread of pests. For temperature-sensitive wines, reefer containers (also known as refrigerated shipping) are essential to maintain quality during transit.

Packaging: Don’t Cut Corners on Protection

Packaging plays a critical role in ensuring your beverages arrive intact and presentable. Wine, beer and spirits are fragile goods and poor packaging is one of the leading causes of damage during transit.

At Kukla UK, we recommend using only industrial-grade packaging materials that are specifically designed for logistics, not household alternatives.

- Cases should be sturdy and stackable, preferably made from double-walled corrugated cardboard. Avoid flimsy boxes, which can buckle under pressure during transit.

- Use internal dividers or partitioned inserts to keep bottles separated and prevent clinking, shifting or breakage.

- Bubble wrap is a great cushioning option but only if it’s industrial strength. Domestic bubble wrap is often too thin and prone to puncture. Look for heavy-duty rolls with larger bubbles and thicker film for maximum impact protection.

- Avoid using domestic cling film or stretch wrap, as they lack the tensile strength required for pallet stability. Use professional-grade pallet wrap, designed to secure heavy loads and withstand multiple handling points.

- Edge protectors, anti-slip mats, and cardboard layer sheets can add stability between layers on the pallet and absorb shock from sudden movement or rough surfaces.

Investing in the right materials not only protects your goods but also reduces claims, delays and reputational damage caused by broken or leaking bottles.

What If Your Load Is Irregular?

Not every shipment fits neatly on a pallet. For irregular or unusual loads:

- Box items where possible.

- Wrap and protect fragile edges.

- Use extra strapping or ratchet bands.

- Centre delicate goods on the pallet for added protection.

At Kukla UK, We Help You Get It Right

We aim to reduce handling throughout the logistics journey, as the fewer times your load is touched, the lower the risk of damage. We work closely with our customers and suppliers to ensure palletisation is correct from the outset, preventing rejected loads and costly delays.

So, while pallets may not be the most exciting part of wine and beverage logistics, they’re one of the most important. A well-packed pallet is your first step towards a smooth delivery and a satisfied customer.

Need Help With Beverage Logistics?

Whether you’re shipping a few cases or a full container load, Kukla UK has the expertise to get your goods where they need to go — safely, efficiently, and with care. Contact us for tailored advice or a quote today.

Did You Know?

The modern pallet has its roots in ancient “skids”, simple wooden platforms used as far back as Ancient Egypt. However, it wasn’t until the invention of the forklift truck in 1915 that pallets, as we know them today, began to take shape.

The first formal pallet patent was filed in 1925 by Howard T. Hallowell, who called it a “Lift Truck Platform”. During World War II, pallet use skyrocketed, driven by the military’s need for rapid, large-scale transportation of supplies. Innovations from this era include the development of the four-way pallet, which allowed forklifts to lift from any side.

Following the war, patents surged, including the first four-way pallet by Robert Braun and the first disposable pallet by Norman Cahners, both of which were introduced in 1945. These wartime innovations laid the groundwork for the global supply chain infrastructure we rely on today.

Frequently Asked Questions (FAQs)

What type of pallet should I use for shipping wine or spirits?

The most common pallet types for beverages are Euro pallets (800 x 1200 mm) and VMF block pallets (1000 x 1200 mm). Euro pallets are widely used throughout Europe, whereas VMF pallets are specifically designed for transporting glass and bottles.

How many cases can fit on one pallet?

A standard pallet can typically hold 48 to 56 full 12-bottle cases of wine, depending on bottle size and packaging configuration.

Can I mix different products on the same pallet?

Technically, yes, but it is not recommended unless absolutely necessary. If the paperwork for one product is incorrect, the entire pallet can be held up at customs, resulting in costly delays. Keep contents homogeneous to minimise risk.

Do I need to wrap and secure the pallet myself?

Yes, if you’re loading the pallet, it must be banded and shrink-wrapped securely. Poorly prepared pallets can be refused for collection or become unstable in transit.

What is ISPM 15 and why does it matter?

ISPM 15 is a global standard requiring heat treatment or fumigation of wooden pallets to prevent the spread of pests. If your pallets aren’t compliant, they could be rejected at international borders.

Can Kukla handle both small and large volume shipments?

Yes. Whether you’re sending a few pallets or a full container, Kukla UK can scale our logistics solutions to your business size and needs.

Can Kukla UK help with pallet preparation or advice?

Absolutely. Our team can advise on the best practices for pallet loading, provide documentation support, and help ensure your shipments meet all regulatory requirements. Just get in touch.