When you think about logistics for wine, beer, or spirits, the focus is often on packaging, shipping lanes, or pallets. But for temperature-sensitive goods, there’s another critical element at play: the refrigerated container, better known in the trade as the reefer.

At Kukla UK, we know that maintaining the right temperature isn’t just a technical detail; it’s fundamental to preserving quality from origin to final delivery. Whether you’re moving premium wines, craft beers, or spirits that need climate stability, reefer containers are the backbone of controlled beverage logistics.

Why Reefer Containers are Essential in Beverage Logistics

A reefer container is essentially a mobile refrigeration unit. Available in standard 20ft and 40ft sizes, these containers are fitted with integral cooling systems powered during transit by the vessel, truck, or terminal connection. There is also a short sea 45ft option from Europe, along with road trailers. The role of reefer containers is simple yet vital: maintain a stable climate regardless of outside conditions.

Why it matters for beverages:

Protection from Heat and Cold – Beverages are sensitive to both extremes; prolonged exposure can affect flavour, quality, or even packaging integrity.

Consistency Across Long Journeys – From hot summers to harsh winters, reefers ensure products experience a consistent environment.

Global Reach – Temperature-controlled shipping opens markets further afield without compromising quality.

How Reefers Work

Reefer containers operate like large-scale refrigerators. They don’t actively cool a warm load; instead, they maintain a pre-set internal temperature (typically between -25°C and +25°C, depending on the cargo). For wines and spirits, the recommended storage temperature is +12°C, with a maximum of +14 °C, regardless of the outside temperature.

Key features include:

- Integrated Air Circulation – Ensures even temperature distribution across the container.

- Humidity Control – Critical for avoiding label damage, cork deterioration, or condensation inside cartons.

- Data Logging – Modern reefers are equipped with monitoring systems that track temperature and performance throughout the voyage.

Best Practices for Beverage Loads in Reefers

Just as with pallets, loading discipline matters:

- Pre-cool Before Loading – Goods should be stabilised at the required temperature before entering the container.

- Airflow Matters – Stacking patterns must allow cold air to circulate; blocking floor ducts or walls reduces efficiency.

- Correct Palletisation – Use Euro or VMF pallets sized to container dimensions, avoiding overhang that could obstruct airflow.

- Sealed and Secured – Proper shrink-wrapping and packaging help prevent condensation damage and maintain load stability.

Adding Value with Temperature-Controlled Logistics

We work closely with clients to match the right reefer solution to their needs, whether this is a road movement from Europe into the UK, a short-haul service for high-value wines and spirits, or regular global lanes. Our experienced team oversees every stage of the process, ensuring loads are correctly prepared, monitored, and delivered without issue.

So while reefers may not be the most visible part of beverage logistics, they are certainly an important one. From cross-Channel imports to worldwide shipping, they ensure quality is preserved every step of the way.

Reefer Availability in 2025: Why the Right Partner Matters

Despite record production of refrigerated containers this year, supply remains tight across many key trade lanes. Older equipment is being retired, demand for perishable goods continues to grow, and congestion at major European ports is limiting availability.

For importers bringing wine, beer, and spirits into the UK, this can mean competition for capacity, particularly during peak seasons. That is why having an experienced partner matters. At Kukla UK, our team closely monitors the market, works with multiple carriers and plans ahead to secure the right reefer equipment for every shipment.

Frequently Asked Questions (FAQs)

What is a reefer container?

A reefer container is a refrigerated shipping container designed to maintain a specific temperature for perishable or temperature-sensitive goods, such as beverages.

What temperature range can a reefer container maintain?

The standard temperature range for most reefers is between -25°C and +25°C. For beverages such as wine and spirits, the recommended storage temperature is +12°C, with an upper safe limit of +14°C, to maintain quality during transport.

How many pallets fit inside a reefer container?

Depending on pallet type and load configuration, a 20ft reefer can usually carry 10 Euro pallets and 9 standard pallets, while a 40ft reefer can hold 24 euro pallets or 20 standard pallets. A 45ft reefer can hold 31- 32 euro pallets or 25 standard pallets. Weight needs to be considered, too, especially in 45ft containers, as the weight of this type is higher than that of a standard container.

Do beverages need to be pre-cooled before loading into a reefer?

Yes. Reefers are designed to maintain, not rapidly reduce, temperatures. Cargo should be pre-chilled to the desired temperature before loading.

Can reefer containers control both humidity and temperature?

Yes. Modern reefer containers are fitted with humidity-control functions, which are particularly important for wine and spirits. This prevents cork drying, label damage, and condensation issues during transit.

What is the typical transit time for beverages from Europe into the UK using a reefer?

Short-haul reefer road transport from major wine regions in France, Spain, or Italy to the UK typically takes between 2 and 5 days, depending on origin and customs clearance. For sea freight movements from European ports, transit can range from 5 to 10 days, depending on schedules and routing.

Do I need to worry about customs delays when using a reefer?

Yes, delays can occur if documentation is incomplete or inaccurate. Because reefer cargo is perishable, it is often prioritised at ports — but any issues with paperwork can still lead to holds. Ensuring accurate customs declarations and product codes is essential.

Are reefer containers in short supply in 2025?

Yes. Even though global production of reefers has increased, demand for temperature-controlled equipment continues to outpace supply, especially during peak seasons and on high-traffic European trade lanes. Importers into the UK should plan ahead, as availability can be tight. Working with experienced logistics partners like Kukla UK helps secure the right capacity and ensures smooth delivery.

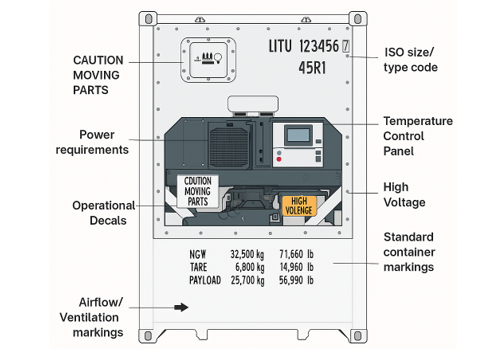

Markings on Reefer Containers

Unlike standard dry containers, reefers carry additional markings and labels on the machinery end. These include the temperature control panel, electrical power requirements, and safety warnings such as High Voltage or Caution: Moving Parts. Operational decals, airflow instructions, and the refrigeration unit’s identification plate are also present, alongside standard container markings like ID numbers, ISO codes, and weight limits. This ensures handlers can safely connect, operate, and maintain the unit during transit.

What’s the difference between a reefer ship and a reefer container?

Reefer ships are specialised vessels built with refrigerated holds. Reefer containers, by contrast, integrate with standard container logistics, making them more flexible and widely used today.

Can Kukla UK arrange temperature-controlled shipping for small or large loads?

Absolutely. We offer flexible solutions, from groupage shipments (sharing space in a reefer) through to full container loads, tailored to your specific requirements.

Did You Know?

- In 1882, the ship Dunedin became the first refrigerated vessel to deliver frozen meat from New Zealand to the United Kingdom, proving the viability of long-distance cold-chain shipping. Although this shipment was meat, it marked a pivotal moment in maritime refrigeration and paved the way for future temperature-controlled imports like beverages into the UK.

- The word “reefer” comes from the verb to reef, once used in sailing when reducing sails against strong winds. Over time, it became slang for refrigerated ships and containers; it has nothing to do with its other modern-day meanings.